http://www.microchip.com/stellent/idcplg?IdcService=SS_GET_PAGE&nodeId=1824&appnote=en011794

In many applications, a DC/DC Converter is used to produce a regulated voltage or current,

derived from an unregulated power supply, or from a battery.

Examples of these applications include battery chargers, electronic air purifiers,

emergency exit signs, and distributed power systems.

In some of those applications, a dedicated Switched Mode Power Supply (SMPS) Controller IC

is used in conjunction with a microcontroller.

In other applications, however, a dedicated SMPS Controller IC may be overkill.

An alternative approach is to generate a low cost SMPS function in a smart microcontroller,

such as the PIC16C620A.

This Application Note shows a method of using the microcontroller to perform simple SMPS control functions.

Two circuits were built for evaluation.

One circuit provides a Constant Voltage output,

the other a Constant Current output

DC/DC CONVERTER

There are several popular DC/DC Converter topologies, such as the Boost and Fly-back Converter topologies.

The DC/DC Converter used in this example is a Buck (or step down) Converter, which is also a popular topology.

In Figure 3, the Buck Converter consists of transistor Q1, diode D1, inductor L1, and capacitor C1.

Transistor Q2 is used as a level translator for the PICmicro device PORTB output to turn Q1 on or off.

Application Note AN701 explains how a Buck Converter works. It also provides a general guideline on component selection.

In any type of DC/DC Converter circuit, the power device selections are very important.

The key parameters to look for in the transistor Q1 are the switching time and current rating.

These two parameters greatly affect the maximum switching frequency of the converter,

and also how much current the converter can be designed for.

The diode D1 should either be a Schottky, or ultra fast diode, in order to minimize switching losses in the converter.

The type of capacitor C1 is also very important to minimize the ripple on the converter output.

An electrolytic capacitor with a low ESR (Equivalent Series Resistance) is desirable for capacitor C1.

In some cases, the output ripple of the converter may still be higher than desired,

even with the proper inductor and capacitor selections.

In this case, an additional inductor and capacitor may be used as a low pass filter at the converter output.

A DC/DC Converter is normally chosen because of its high efficiency in converting the input power to output power.

Unlike a linear regulator, the efficiency measure of a DC/DC Converter generally increases as its load increases.

A properly designed DC/DC Converter can yield an efficiency measure of greater than 90% at full load.

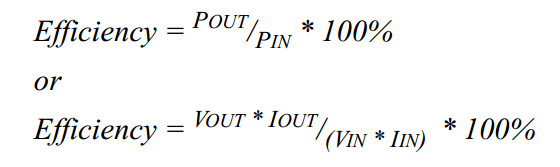

The efficiency of a DC/DC Converter is expressed as the ratio of output power and input power.

The following equations can be used to determine efficiency

The selection of the DC/DC Converter components, in many cases, is a trade-off between cost, performance, and size.

In this Application Note, the component selections were made to simply provide a DC/DC Converter

that can be used to demonstrate the PIC16C620A capability to perform SMPS controller function.

The DC/DC Converter discussed here is not optimized for any particular parameter.

SMPS CONTROLLER FUNCTION

The DC/DC Converter circuit is merely a power processor.

It transforms the available input voltage and current into the output voltage and current,

based on the command of the SMPS controller.

The SMPS controller looks at the converter output, compares the output to a set point,

performs a control algorithm and finally, applies the algorithm output to a modulator.

The modulator output is then used to drive the DC/DC Converter.

Figure 1 shows a simplified block diagram of a complete DC/DC Converter system.

In this Application Note, the PIC16C620A is used to implement the SMPS controller function,

which includes the following functions:

set point generation,

error amplifier,

control algorithm, and

the modulator.

These functions are shown inside the dashed box in Figure 1.

MODULATOR - PULSE SKIPPING MODULATION (PSM)

One of the simplest modulation techniques used for controlling a DC/DC Converter is Pulse Skipping Modulation (PSM),

which is also known as Pulsed Frequency Modulation.

In a PSM system, the modulator generates a train of pulses to turn the converter power switch on and off.

The pulses have a fixed pulse width, as well as period.

As long as the converter output is below the desired target, the PSM pulses continue to run the converter switch.

Once the converter output reaches or exceeds the target, the next PSM pulse is skipped.

This operation will result in decreasing pulse density as the converter output reaches its target, or as the output loading decreases.

When the converter output falls below the target, or as the output loading increases, the PSM pulse density will increase.

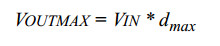

The theoretical limit of the maximum output voltage is determined by the input voltage to the DC/DC Converter

and the maximum duty cycle of the PSM signal, which is the duty cycle of the PSM signal when it is continuously running (not skipping pulses).

This relationship can be expressed as follows:

This formula does not take into account the conduction and switching losses of the converter components.

The discussion of non-ideal DC/DC Converter is beyond the scope of this Application Note.

However, many papers and text books are available on this subject.

In this application, the PIC16C620A microcontroller performs the modulator function in firmware.

This firmware modulator generates the PSM pulses on the RB7 pin (PORTB, bit 7),

to drive transistor Q2 of the DC/DC Converter.

When the DC/DC Converter output is below the desired value,

the firmware continuously sends out PSM pulses to increase the converter output.

Once the DC/DC Converter output exceeds the target, the controller will skip the PSM pulses

until the output voltage, or current, falls below the threshold and the control cycle repeats.

Timer0 of the microcontroller is used to generate a time base for the firmware modulator.

Timer0 is enabled and the TMR0 register is loaded with a reload value.

When Timer0 overflows, an interrupt occurs. In the interrupt routine, TMR0 is again loaded with the reload value.

The reload value determines the time base of the PSM signal.

In this application, the TMR0 reload value is chosen to produce a time base of 50 microseconds

when the microcontroller runs from a 16 MHz crystal. Other crystal frequencies may be used;

however, the 16 MHz was selected to give plenty of instruction cycles in between Timer0 interrupts,

for the firmware execution. When the actual application requirements are well defined,

the operating frequency can be adjusted to a lower frequency to save power

FEEDBACK CIRCUIT

For the SMPS controller to work properly, the DC/DC Converter system must include a feedback circuit.

The feedback circuit provides information to the SMPS controller of the converter output.

Feedback Circuit for Constant Voltage DC/DC Converter

The first circuit is a Constant Voltage DC/DC Converter.

The feedback requirement for a Constant Voltage control is a voltage proportional to the output voltage.

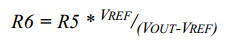

In Figure 3, this feedback circuit consists of R5 and R6.

The output of the R5-R6 divider is applied to the AN1 input pin of the C2 comparator in the PIC16C620A.

The two resistors simply scale down the output voltage to equal the reference voltage.

The formula to calculate R5 and R6 is shown below

The parallel combination value of R5 and R6 should be less than 10 kΩ to minimize errors

due to input leakage current from the AN1 pin.

Some applications require that the feedback voltage can be trimmed to compensate for the VREF variations over process.

If this capability is required, then a potentiometer can be added to allow trimming.

To get the most accurate results, the adjustment of the trim potentiometer should be performed when the system is running.

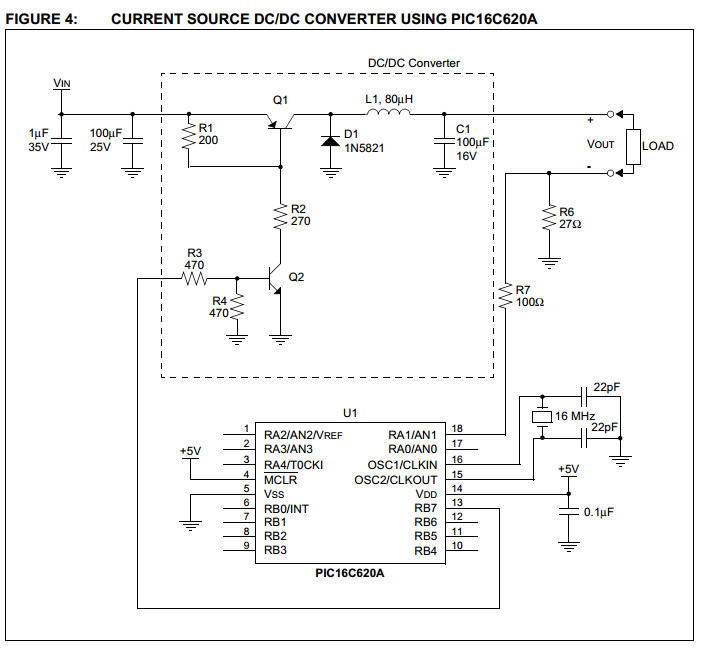

Feedback Circuit for Constant Current DC/DC Converter

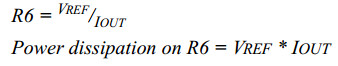

The second circuit is a Constant Current DC/DC Converter.

The feedback requirement for this circuit is a voltage proportional to the output current.

For the Constant Current circuit in Figure 4, the feedback consists of simply R6. The voltage on R6 is then

presented to the AN1 input pin of the C2 comparator in

the PIC16C620A. Resistor R7 is added to provide ESD

protection to the AN1 pin, since the load will be connected to R6 directly. The formula to calculate R6 is:

for applications where the output current is high, a very small current sense resistor, R6, is required to minimize power dissipation.

In this case, an operation amplifier may be required to amplify the small voltage on R6 to the size of VREF.

Similar to the Constant Voltage applications, depending on the need,

a trimming potentiometer may be required in the Constant Current application as well.

Since potentiometers are generally not designed to dissipate power,

it is very important to make sure that the potentiometer does not carry the load current,

for reliability and control drift minimization reasons.

Output Load Connections for the Constant Current DC/DC Converter

For the circuit shown in Figure 4, the load connections for the Constant Current circuit can not be grounded.

If the load is grounded, then the current sense resistor R6 is shorted to ground and the SMPS controller can not sense the load current.

If a grounded load is required in the system, the method for current sensing must be modified.

The following are possible solutions to allow a ground referenced load:

1. Ground the load and float the PICmicro microcontroller ground.

2. Move the current sense resistor to the output of the DC/DC Converter and use an op-amp

to level shift the voltage on R6 to a ground referred signal.

SET POINT AND VOLTAGE CONTROL ALGORITHM

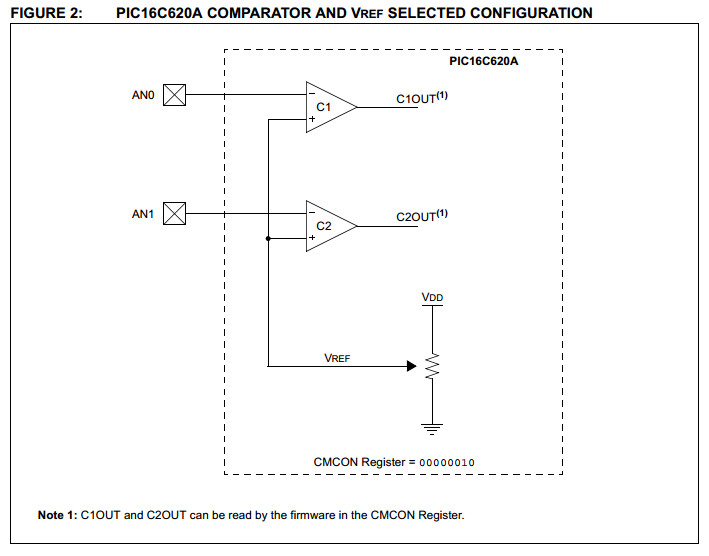

The PIC16C620A has an on-board voltage reference, VREF, and two comparators, C1 and C2 (see Figure 2 for illustration).

The VREF module is used to provide a set point to the system.

If so desired, the set point voltage can be adjusted via firmware.

In this application, the VREF set point is set to VDD/2.

The comparators have several configurations, some of which allow the comparators to compare external voltage(s) to the VREF voltage.

The configuration that is used for this application example is shown in Figure 2.

To select this configuration, the comparator control register CMCON must be set to b’00000010’.

In this application, only the C2 comparator of the

PIC16C620A is used to compare the feedback voltage

on the AN1 pin to the internal voltage reference VREF.

If the DC/DC Converter output is lower than the desired

value, then the feedback voltage presented on AN1 is

lower than VREF. In this case, the comparator output,

C2OUT, is high. If the DC/DC Converter output is

higher than the desired value, then the comparator output is low. The firmware uses the comparator output

state to determine whether the DC/DC Converter output needs to be increased or not.

The Voltage Control Algorithm performed in firmware

becomes very simple:

• If the voltage on AN1 pin is lower than VREF, then

produce PSM output pulse

• Else (voltage on AN1 pin is higher than VREF),

then skip PSM output pulse

Because the PIC16C620A and the firmware monitors

and controls the voltage on the AN1 pin, regardless of

whether the voltage is derived from either the Constant

Voltage or Constant Current feedback circuit, this firmware can be used for either the Constant Voltage or

Constant Current circuit implementation without any

changes.

Integrating the Voltage Control and Modulator

The Voltage Control Algorithm is executed every time

Timer0 interrupts. After the firmware reloads TMR0, it

checks the comparator output to determine whether the

output pulse should be active or not, on the next PSM

cycle. Once this decision is made, a flag bit is set or

cleared depending on the decision, and the output

pulse is turned off. After several microseconds delay,

before leaving the interrupt routine, the output pulse is

activated again, depending on the status of the flag bit.

If the output is set, this pulse will stay active until the

next Timer0 interrupt occurs. If the output is clear, then

the PSM pulse is skipped until the next Timer0 interrupt

occurs, and the control sequence repeats. Figure 5

shows the flowchart of the Firmware SMPS Controller.

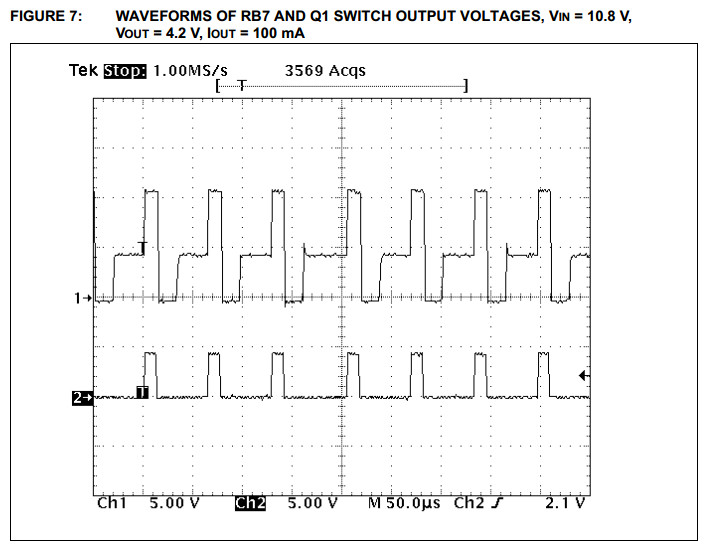

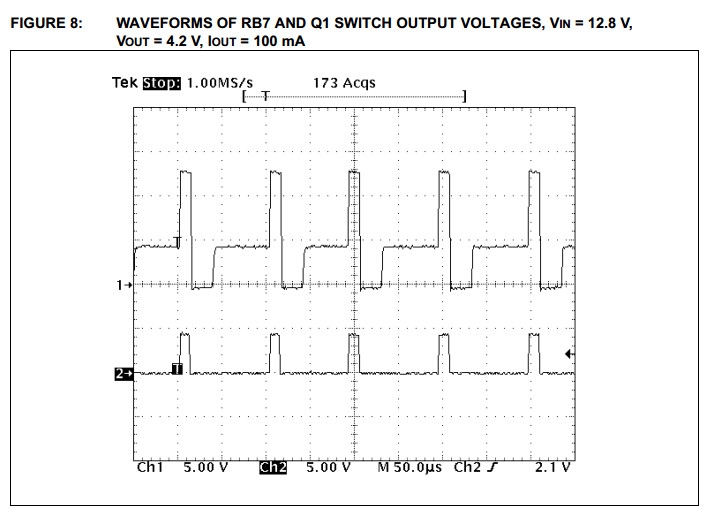

WAVEFORMS FROM THE VOLTAGE

SOURCE CIRCUIT

To see how the DC/DC Converter circuit works, voltage

waveforms of the PSM output on RB7 and the Q1

switch output are captured for 3 different input voltage

levels, while the output load is kept constant at 4.2 V,

100 mA. The RB7 PSM output voltage is shown as

Channel 1, while the Q1 switch output voltage is shown

as Channel 2. The waveforms are captured at the following input voltage levels:

1. VIN = 8.8 V. See Figure 6.

2. VIN = 10.8 V. See Figure 7.

3. VIN = 12.8 V. See Figure 8.

When the RB7 output is high, the Q1 switch turns on.

The switch output voltage immediately rises to the input

voltage, i.e., 8.8 V on Figure 6. At this time, the inductor

current increases. The inductor current is flowing to the

capacitor C1 and the DC/DC Converter load. Once the

RB7 output goes low, the Q1 switch turns off. The

inductor current, however, needs a low impedance path

to continue its flow. This causes the switch output voltage to fall until diode D1 turns on. The inductor current

now flows through the diode from the system ground.

Figure 6 shows that the voltage at the output of the

switch drops to approximately -0.7V. At this time, the

voltage across the inductor reverses its polarity, causing the inductor current to drop. When the inductor current reaches zero, diode D1 turns off, and the voltage

on the inductor collapses to zero. This can be seen by

the Q1 switch output going from -0.7V to the DC/DC

Converter output voltage.

Note that although the waveform seems repetitive, the

frequency is not constant. Once in a while, the distance

between pulses changes. This change happens when

the Voltage Control Algorithm determines that additional pulses should be skipped for that PSM cycle.

The waveforms on Figure 6, Figure 7 and Figure 8,

were taken with the same voltage and time scales. It is

obvious from looking at the three plots, as the ratio of

VIN/VOUT increases, the pulse density on the RB7 pin

decreases. At higher input voltages, each switching of

the Q1 transistor will deliver higher charge to the DC/

DC Converter output.

For a constant input voltage, the PSM pulse density on

the RB7 pin will also vary as a function on the output

load. In the Constant Voltage circuit, as the output current decreases, the PSM pulse density on the RB7 pin

also decreases.

FIGURE 6: WAVEFORMS OF RB7 AND Q1 SWITCH OUTPUT VOLTAGES, VIN = 8.8 V,

VOUT = 4.2 V, IOUT = 100 mA

BENCH MEASUREMENTS DATA

To quantitatively evaluate performance, each circuit

was tested in the lab. Several key parameters relevant

to power supply circuits were measured. Those parameters are:

1. Line Regulation: both Constant Voltage and

Constant Current circuits.

Line regulation is the amount of change on the

output as a function of the input voltage. For the

Constant Voltage circuit, the units for line regulation are V/V, while for the Constant Current

they are A/V (or mA/V).

2. Load Regulation: both Constant Voltage and

Constant Current circuits.

Load regulation is the amount of change on the

output as a function of the load. For the Constant Voltage circuit, the units for load regulation

are V/A (or mV/mA), while for the Constant Current they are A/V (or mA/V).

3. Output Ripple Noise: Constant Voltage only.

The output ripple noise is measured in mV rms.

4. Power Conversion Efficiency: Constant

Voltage only.

The Efficiency is measured as the ratio of power

delivered to the load and power delivered to the

DC/DC Converter.

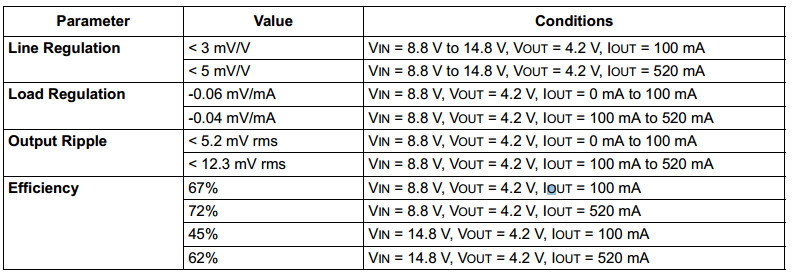

Bench Measurement Data of the Constant

Voltage DC/DC Converter

The following table is a summary of the Constant Voltage DC/DC Converter performance.

TABLE 1: CONSTANT VOLTAGE DC/DC CONVERTER PERFORMANCE

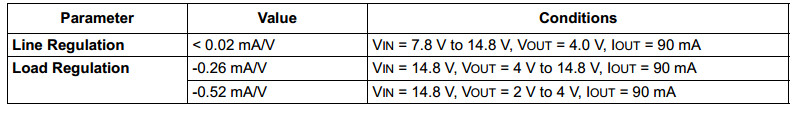

Bench Measurement Data of the Constant

Current DC/DC Converter

The following table is a summary of the Constant Current DC/DC Converter performance. The output ripple

current of this circuit was not measured. The Efficiency

parameter was also not measured. The Efficiency measure, however, should be identical to that of the Constant Voltage DC/DC Converter for a given similar input

and output condition to the circuit.

TABLE 2: CONSTANT CURRENT DC/DC CONVERTER PERFORMANCE

EXPANDING THE APPLICATION

The use of the PIC16C620A in DC/DC Converter circuits can be expanded to the following applications:

1. Constant Voltage with Current Limit DC/DC

Converters.

Since the PIC16C620A has two comparators,

one comparator can be used for the voltage

feedback, and the other for detecting current

limit.

2. Other power converter topologies.

The control methodology can be used for Boost

and Fly-back topologies, as well. The feedback

circuitry, more than likely, must be modified to

include the power switch current sensing.

3. Firmware programmable output voltage or

current.

The VREF voltage can be changed in firmware.

This capability allows user to change the output

voltage or current as needed by the application.

4. The use of other modulation techniques, i.e.,

Pulse Width Modulation (PWM).

A PWM control can be implemented, instead of

the PSM technique used in this example. In

addition to Timer0 interrupt, the comparator

interrupt is also enabled. In this case, the comparator interrupt determines when to turn off the

RB7 output pulse as soon as the control threshold is reached. In this type of PWM control, however, it is possible for the PWM signal to oscillate

when the duty cycle is greater than 50%, due to

a phenomenon called the Right Half Plane Zero.

Under this condition, a slope compensation is

required to stabilize the PWM control signal.

The detailed implementations of any of those applications are left as an exercise to the readers’ creativity.

USION

This Application Note has demonstrated that the

PIC16C620A can be used to perform simple SMPS

controller functions, such as Constant Voltage, Constant Current, or Constant Voltage with current limit.

The program example can be used with any of the

PICmicro family members, which has on-board

comparators.

REFERENCES

1. PIC16C620A Datasheet, DS30235 revision H or

newer

2. AN701: Switch Mode Battery Eliminator Based

on a PIC16C72A

1 ; 2 ; Software License Agreement 3 ; 4 ; The software supplied herewith by Microchip Technology Incorporated 5 ; (the 揅ompany? for its PICmicro?Microcontroller is intended and 6 ; supplied to you, the Company抯 customer, for use solely and 7 ; exclusively on Microchip PICmicro Microcontroller products. The 8 ; software is owned by the Company and/or its supplier, and is 9 ; protected under applicable copyright laws. All rights are reserved. 10 ; Any use in violation of the foregoing restrictions may subject the 11 ; user to criminal sanctions under applicable laws, as well as to 12 ; civil liability for the breach of the terms and conditions of this 13 ; license. 14 ; 15 ; THIS SOFTWARE IS PROVIDED IN AN "AS IS" CONDITION. NO WARRANTIES, 16 ; WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING, BUT NOT LIMITED 17 ; TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A 18 ; PARTICULAR PURPOSE APPLY TO THIS SOFTWARE. THE COMPANY SHALL NOT, 19 ; IN ANY CIRCUMSTANCES, BE LIABLE FOR SPECIAL, INCIDENTAL OR 20 ; CONSEQUENTIAL DAMAGES, FOR ANY REASON WHATSOEVER. 21 ; 22 ;============================================================================== 23 ;File name: dc-dc1.asm 24 ; 25 ;This program demonstrates how a PICmicro with comparator, ie: PIC16C620A, 26 ;can be used to control voltage or current, such as in a switched mode dc/dc 27 ;converter. This example employs the pulse skipping modulation (psm) technique 28 ;to drive the external power converter circuit. 29 ; 30 ;============================================================================== 31 ;author: Hartono Darmawaskita 32 ;company: Microchip Technology, Inc. 33 ;date: 02-11-2000 34 ;MPLAB version: 4.12.12 35 ; 36 ;============================================================================== 37 LIST P = 16C620A, F=INHX8M 38 #INCLUDE <P16C620A.INC> 39 __config _WDT_OFF & _HS_OSC & _BODEN_ON & _PWRTE_ON 40 41 ;Pin definition 42 #define PULSE PORTB,7 ;pulse output to the power transistor 43 44 ;Constants 45 VREF_HI equ b'10101100' ;high voltage setpoint, vref = vdd/2 46 VREF_MID equ b'10100110' ;mid voltage setpoint, vref = vdd/4 47 VREF_LO equ b'10100010' ;low voltage setpoint, vref = vdd/12 48 TMR0_RELOAD equ .215 ;reload value for tmr0 49 50 ;RAM 51 FLAG equ 0x20 ;flag register 52 ;bit0 1=feedback voltage is less than setpoint 53 W_TEMP equ 0x24 ;temporary w register 54 STATUS_TEMP equ 0x25 ;temporary status register 55 56 ;============================================================================== 57 org 00 58 goto start 59 ; 60 ;isr is the interrupt service routine. 61 ;in this routine tmr0 is reloaded with the TMR0_RELOAD value. tmr0 operates as 62 ;the time base for the psm modulator. 63 ;the voltage on an0 pin is compared to the vref: 64 ; if an1 > vref, then skip the next psm pulse 65 ; if an1 < vref, then do not skip psm pulse 66 ; 67 org 04 68 isr: movwf W_TEMP ;save w and status 69 swapf STATUS,W 70 bcf STATUS,RP0 71 movwf STATUS_TEMP 72 ; 73 movlw TMR0_RELOAD ;reload tmr0 74 movwf TMR0 75 bsf FLAG,0 76 btfss CMCON,C2OUT ;if van1 > vsetpoint, 77 bcf FLAG,0 ; then skip next pulse 78 bcf PULSE ;turn off output pulse 79 bcf INTCON,T0IF ;clear tmr0 interrupt flag 80 btfss FLAG,0 ;if skip pulse, 81 goto isr_done ; then exit 82 bsf PULSE ;else begin a new output pulse 83 isr_done: 84 swapf STATUS_TEMP,W ;restore w and status, and exit 85 movwf STATUS 86 swapf W_TEMP,F 87 swapf W_TEMP,W 88 retfie 89 ; 90 ; 91 ;start is the main program of this firmware smps controller. 92 ;i/o ports are initialized. 93 ;tmr0 is configured to run from the internal oscillator with no prescalar. the 94 ;tmr0 interrupt is also enabled. 95 ;the comparators and vref modules are initialized. 96 ;the rest of this main program is an infinite loop. if the microcontroller is 97 ;used for other non timing critical functions, the code for these functions 98 ;should reside within the main program. 99 ; 100 start: bcf STATUS,RP0 ;bank0 101 clrf PORTA 102 clrf PORTB 103 bsf STATUS,RP0 ;bank1 104 movlw b'11111111' ; 105 movwf TRISA ;port a lines are all inputs 106 movlw b'00000000' 107 movwf TRISB ;port b lines are outputs 108 movlw b'11011111' ;tmr0 clock is internal, prescaler -> wdt 109 movwf OPTION_REG 110 bcf STATUS,RP0 ;back to bank0 111 ; 112 movlw b'00000010' ;AN0 to C1, AN1 to C2, Internal Vref 113 movwf CMCON 114 ; 115 movlw VREF_HI ;setpoint is vref high 116 bsf STATUS,RP0 ;bank1 117 movwf VRCON 118 bcf STATUS,RP0 ;back to bank 0 119 clrf FLAG 120 ; 121 movlw TMR0_RELOAD ;initialize tmr0 122 movwf TMR0 123 movlw b'10100000' ;enable tmr0 interrupt 124 movwf INTCON 125 ; 126 loop: goto $+1 ;main program for other functions goes here 127 goto loop 128 ; 129 END