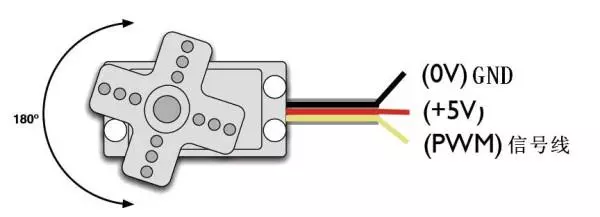

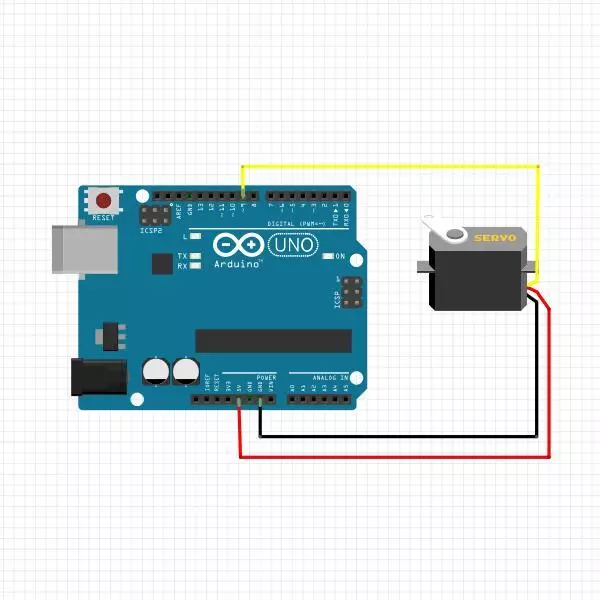

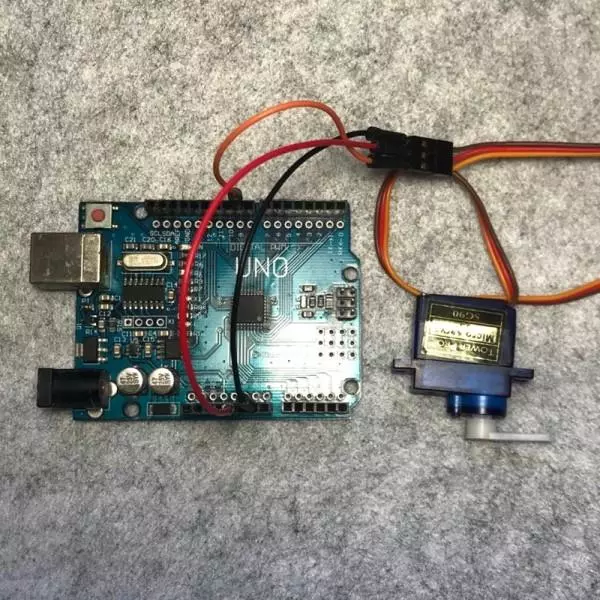

单路电机

#include <Servo.h>

Servo myservo; // 定义Servo对象来控制

int pos = 0; // 角度存储变量

void setup() {

myservo.attach(9); // 控制线连接数字9

}

void loop() {

for (pos = 0; pos <= 180; pos ++) { // 0°到180°

// in steps of 1 degree

myservo.write(pos); // 舵机角度写入

delay(5); // 等待转动到指定角度

}

for (pos = 180; pos >= 0; pos --) { // 从180°到0°

myservo.write(pos); // 舵机角度写入

delay(5); // 等待转动到指定角度

}

}

额外说明: 对于360度舵机 不再是 0-180控制角度,90度停止 0一个方向最大速度转,180另一个方向最大速度转

myservo.write(80); //前转 myservo.write(90); //停止 myservo.write(90); //后转

串口获取消息

#include <Servo.h>

Servo myservo4;

Servo myservo5;

Servo myservo6;

void go4(){

myservo4.write(0);

delay(2000);

myservo4.write(90);

delay(1000);

}

void go5(){

myservo5.write(0);

delay(1000);

myservo5.write(90);

delay(1000);

myservo5.write(180);

delay(1000);

myservo5.write(90);

delay(1000);

myservo5.write(0);

delay(1000);

}

void go6(){

myservo6.write(0);

delay(1000);

myservo6.write(90);

delay(1000);

myservo6.write(180);

delay(1000);

myservo6.write(90);

delay(1000);

myservo6.write(0);

delay(1000);

}

void do_motor(String comdata){

if(comdata=="motor1"){

go4();

}

else if(comdata=="motor2"){

go5();

}

else if(comdata=="motor3"){

go6();

}

else{}

}

void setup() {

//硬串口

Serial.begin(9600);

myservo4.attach(4);

myservo5.attach(5);

myservo6.attach(6);

myservo4.write(90);//S舵机不一样 90代表停止

myservo5.write(0);//普通舵机 初始化0位置

myservo6.write(0);//普通舵机 初始化0位置

}

String comdata;

void loop() {

if(Serial.available()>0){

comdata = Serial.readString();

Serial.println(comdata);

do_motor(comdata);

comdata = "";

}

}

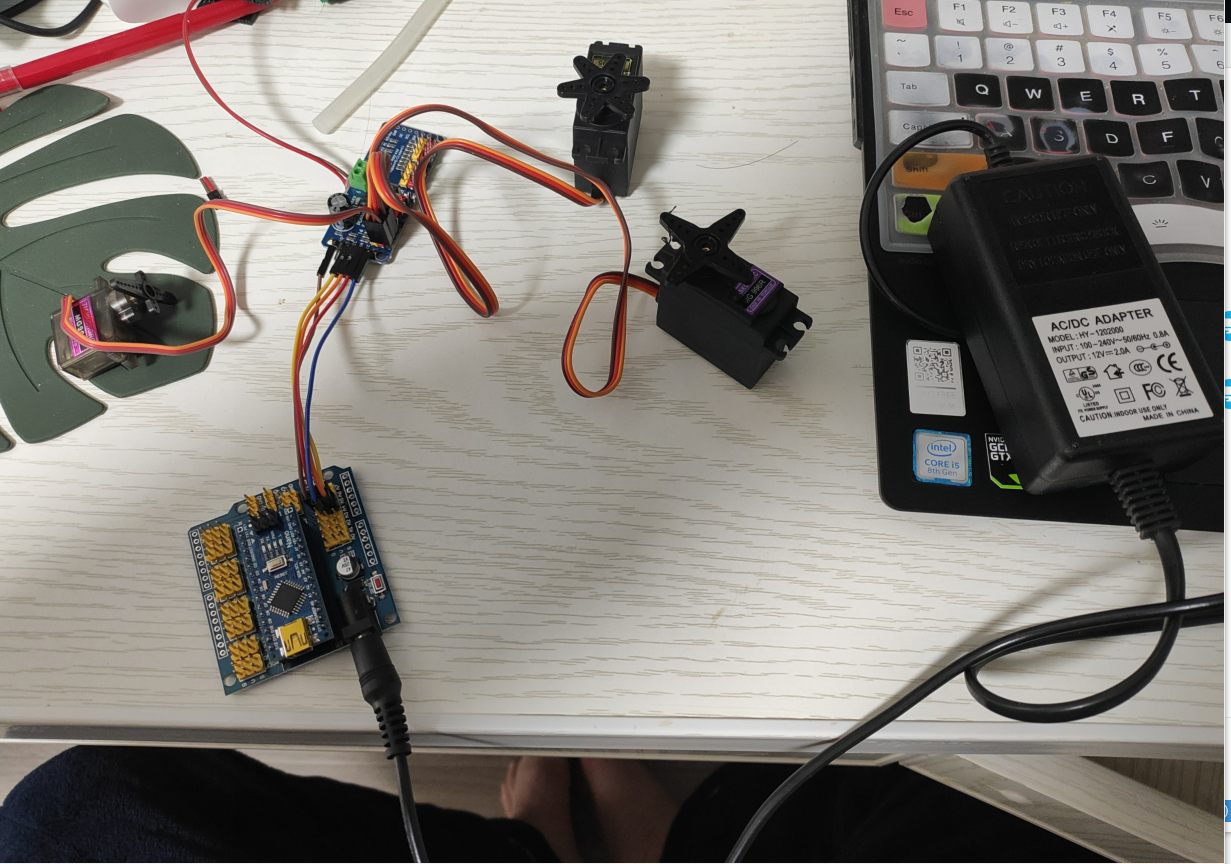

16路电机

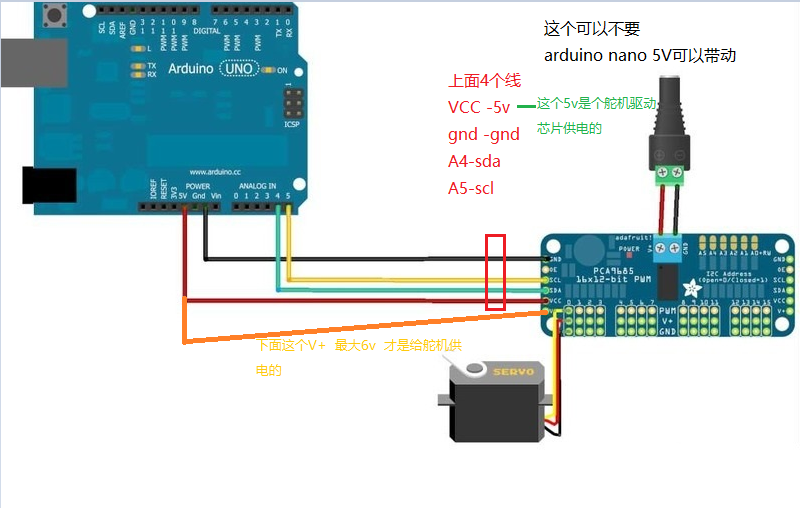

由于Arduino的驱动能力有限,当需要控制多个舵机时,需要外接电源以及使用专用的舵机控制板。

https://item.taobao.com/item.htm?spm=a1z09.2.0.0.435e2e8dKDHquW&id=536890985912&_u=21qf7bf5b2a1

无论是电脑USB供电还是专门12v-2A供电 都可以

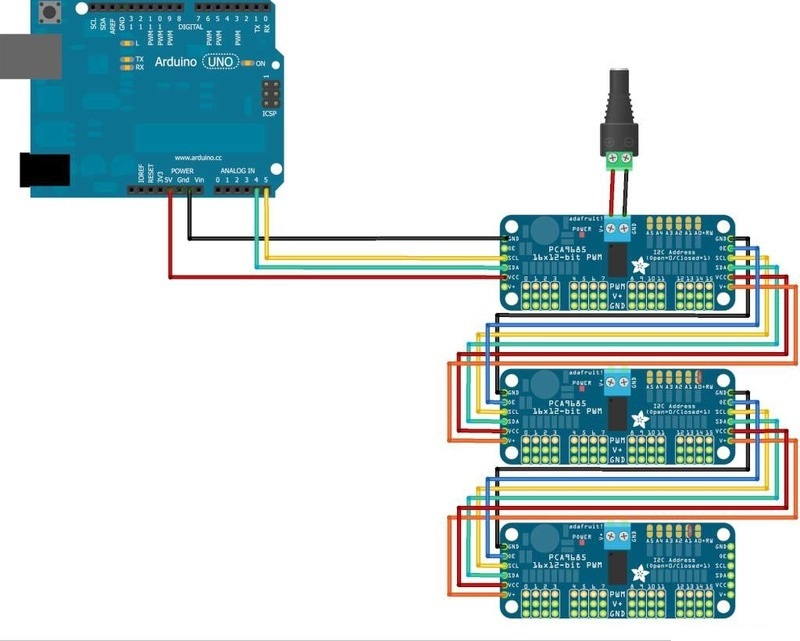

板子可以级练控制多个

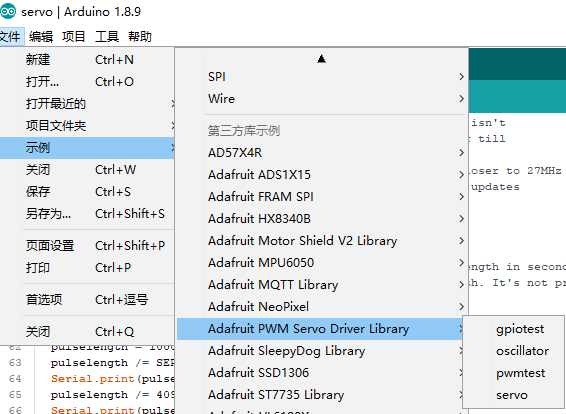

安装库

/***************************************************

This is an example for our Adafruit 16-channel PWM & Servo driver

Servo test - this will drive 8 servos, one after the other on the

first 8 pins of the PCA9685

Pick one up today in the adafruit shop!

------> http://www.adafruit.com/products/815

These drivers use I2C to communicate, 2 pins are required to

interface.

Adafruit invests time and resources providing this open source code,

please support Adafruit and open-source hardware by purchasing

products from Adafruit!

Written by Limor Fried/Ladyada for Adafruit Industries.

BSD license, all text above must be included in any redistribution

****************************************************/

#include <Wire.h>

#include <Adafruit_PWMServoDriver.h>

// called this way, it uses the default address 0x40

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

// you can also call it with a different address you want

//Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver(0x41);

// you can also call it with a different address and I2C interface

//Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver(0x40, Wire);

//根据您的伺服品牌,最小和最大脉冲宽度可能会有所不同 调整它

#define SERVOMIN 150 // This is the 'minimum' pulse length count (out of 4096)

#define SERVOMAX 600 // This is the 'maximum' pulse length count (out of 4096)

#define SERVO_FREQ 50 // Analog servos run at ~50 Hz updates

// our servo # counter

uint8_t servonum = 0;

void setup() {

Serial.begin(9600);

Serial.println("8 channel Servo test!");

pwm.begin();

//理论上内部振荡器是25MHz,但实际上不是

//非常精确。你可以调整这个数字直到

//你得到了你期望的频率!

pwm.setOscillatorFrequency(27000000); // The int.osc. is closer to 27MHz

pwm.setPWMFreq(SERVO_FREQ); // Analog servos run at ~50 Hz updates

delay(10);

}

void loop() {

Serial.println(servonum);

for (uint16_t pulselen = SERVOMIN; pulselen < SERVOMAX; pulselen++) {

pwm.setPWM(servonum, 0, pulselen);

}

delay(500);

for (uint16_t pulselen = SERVOMAX; pulselen > SERVOMIN; pulselen--) {

pwm.setPWM(servonum, 0, pulselen);

}

delay(500);

servonum++;

if (servonum > 3) servonum = 0; // Testing the first 8 servo channels

}

/***************************************************

This is an example for our Adafruit 16-channel PWM & Servo driver

Servo test - this will drive 8 servos, one after the other on the

first 8 pins of the PCA9685

Pick one up today in the adafruit shop!

------> http://www.adafruit.com/products/815

These drivers use I2C to communicate, 2 pins are required to

interface.

Adafruit invests time and resources providing this open source code,

please support Adafruit and open-source hardware by purchasing

products from Adafruit!

Written by Limor Fried/Ladyada for Adafruit Industries.

BSD license, all text above must be included in any redistribution

****************************************************/

#include <Wire.h>

#include <Adafruit_PWMServoDriver.h>

// called this way, it uses the default address 0x40

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

// you can also call it with a different address you want

//Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver(0x41);

// you can also call it with a different address and I2C interface

//Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver(0x40, Wire);

// Depending on your servo make, the pulse width min and max may vary, you

// want these to be as small/large as possible without hitting the hard stop

// for max range. You'll have to tweak them as necessary to match the servos you

// have!

#define SERVOMIN 150 // This is the 'minimum' pulse length count (out of 4096)

#define SERVOMAX 600 // This is the 'maximum' pulse length count (out of 4096)

#define USMIN 600 // This is the rounded 'minimum' microsecond length based on the minimum pulse of 150

#define USMAX 2400 // This is the rounded 'maximum' microsecond length based on the maximum pulse of 600

#define SERVO_FREQ 50 // Analog servos run at ~50 Hz updates

// our servo # counter

uint8_t servonum = 0;

void setup() {

Serial.begin(9600);

Serial.println("8 channel Servo test!");

pwm.begin();

// In theory the internal oscillator is 25MHz but it really isn't

// that precise. You can 'calibrate' by tweaking this number till

// you get the frequency you're expecting!

pwm.setOscillatorFrequency(27000000); // The int.osc. is closer to 27MHz

pwm.setPWMFreq(SERVO_FREQ); // Analog servos run at ~50 Hz updates

delay(10);

}

// You can use this function if you'd like to set the pulse length in seconds

// e.g. setServoPulse(0, 0.001) is a ~1 millisecond pulse width. It's not precise!

void setServoPulse(uint8_t n, double pulse) {

double pulselength;

pulselength = 1000000; // 1,000,000 us per second

pulselength /= SERVO_FREQ; // Analog servos run at ~60 Hz updates

Serial.print(pulselength); Serial.println(" us per period");

pulselength /= 4096; // 12 bits of resolution

Serial.print(pulselength); Serial.println(" us per bit");

pulse *= 1000000; // convert input seconds to us

pulse /= pulselength;

Serial.println(pulse);

pwm.setPWM(n, 0, pulse);

}

void loop() {

// Drive each servo one at a time using setPWM()

Serial.println(servonum);

for (uint16_t pulselen = SERVOMIN; pulselen < SERVOMAX; pulselen++) {

pwm.setPWM(servonum, 0, pulselen);

}

delay(500);

for (uint16_t pulselen = SERVOMAX; pulselen > SERVOMIN; pulselen--) {

pwm.setPWM(servonum, 0, pulselen);

}

delay(500);

// Drive each servo one at a time using writeMicroseconds(), it's not precise due to calculation rounding!

// The writeMicroseconds() function is used to mimic the Arduino Servo library writeMicroseconds() behavior.

for (uint16_t microsec = USMIN; microsec < USMAX; microsec++) {

pwm.writeMicroseconds(servonum, microsec);

}

delay(500);

for (uint16_t microsec = USMAX; microsec > USMIN; microsec--) {

pwm.writeMicroseconds(servonum, microsec);

}

delay(500);

servonum++;

if (servonum > 3) servonum = 0; // Testing the first 8 servo channels

}

不使用扩展版

#include <Servo.h>

Servo myservo; // create servo object to control a servo

Servo myservo1;

int pos = 0; // variable to store the servo position

void setup()

{

Serial.begin(9600);

myservo.attach(9); // attaches the servo on pin 9 to the servo object

myservo.write(90);

myservo1.attach(7);

delay(15);

}

void loop()

{

char ch = Serial.read();

switch(ch){

case 's':

{

myservo.write(80);

delay(1000);

Serial.println("N is inputed");

myservo.write(90);

myservo1.write(0);

delay(1000);

break;

}

case 'n':

{

myservo.write(100);

delay(1000);

Serial.println("S is inputed");

myservo.write(90);

myservo1.write(180);

delay(1000);

break;

}

}

}